In applications like concert show lighting, architectural lighting, and cinema projection, achieving good color mixing and variable spot size is essential. The optics design in front of a RGBW LED source must include optimization for color uniformity as well as beam shape.

A common solution is to place diffuse materials in the optical path. This can provide a good color mix but has negative trade-offs including increased etendue and light losses. These schemes are not suitable when tight beam angles are required.

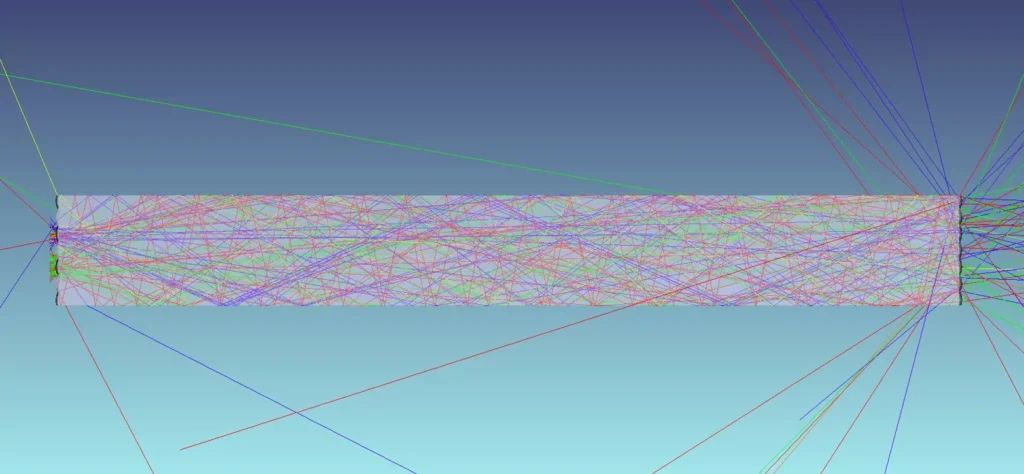

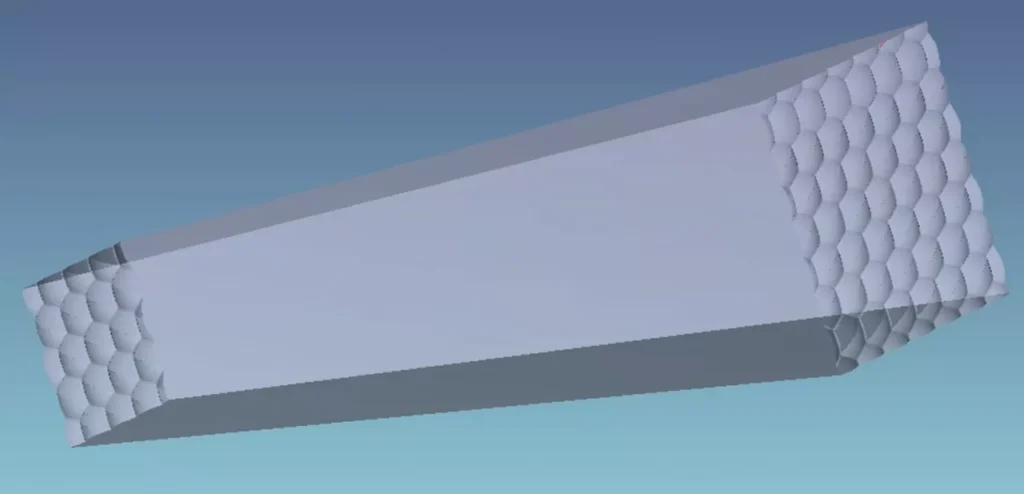

One design approach for narrower beam angles is color mixing rods. In the images below, that approach is explained.

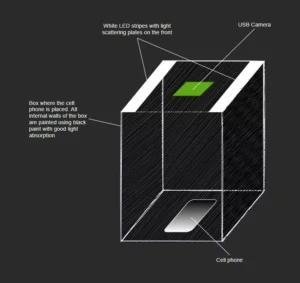

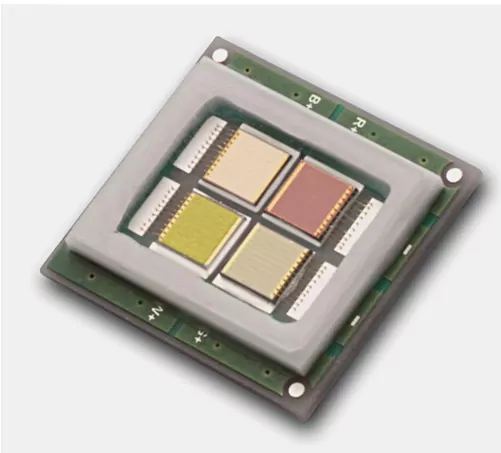

A typical RGBW LED is shown in the first image. Knowing the die location in LED is important. Some LED suppliers use mixed die location in their products (such as luminus LZC-03MD07 LED). In that arrangement, the diffusion option is the correct approach.

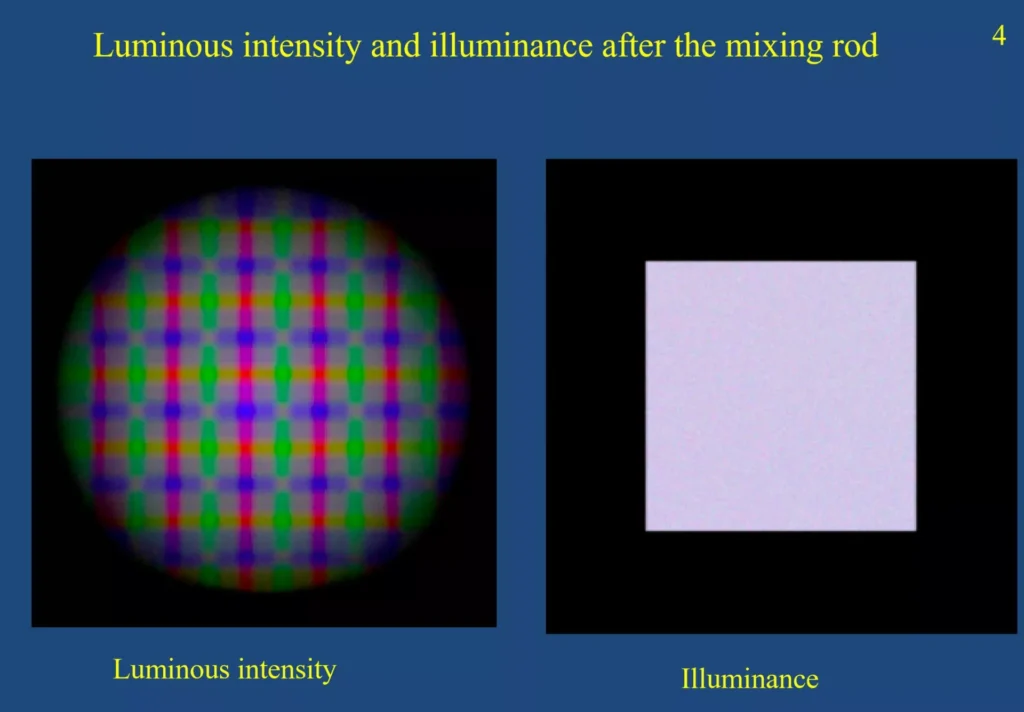

A simple glass or clear plastic rod produces an even color illuminance at the end surface if the LED is placed at the opposite aperture. The luminous intensity is however poorly color mixed. The light is collimated but the luminous intensity profile is also transferred. See images below

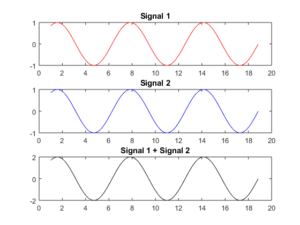

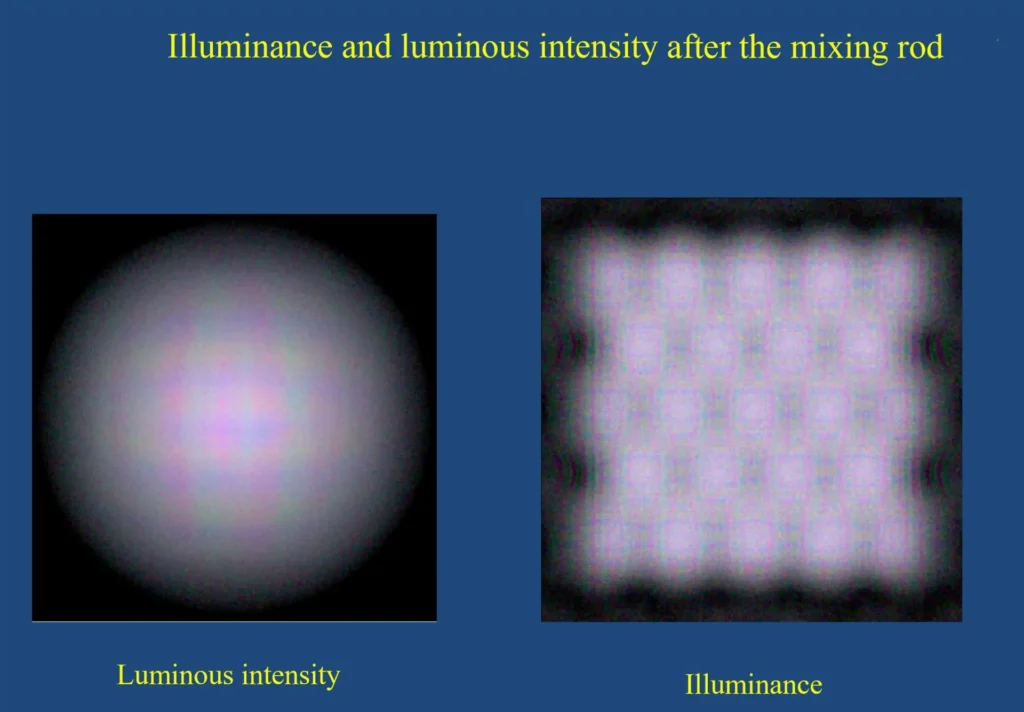

By adding a microlens array at both rod ends, we can achieve a mixed color luminous intensity.

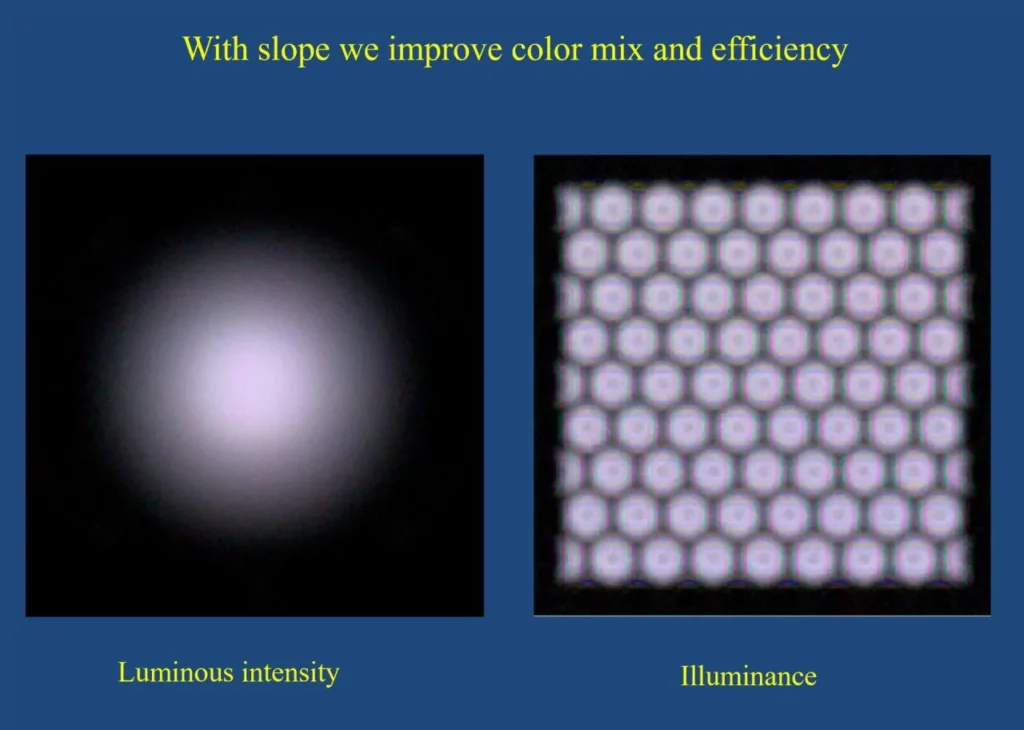

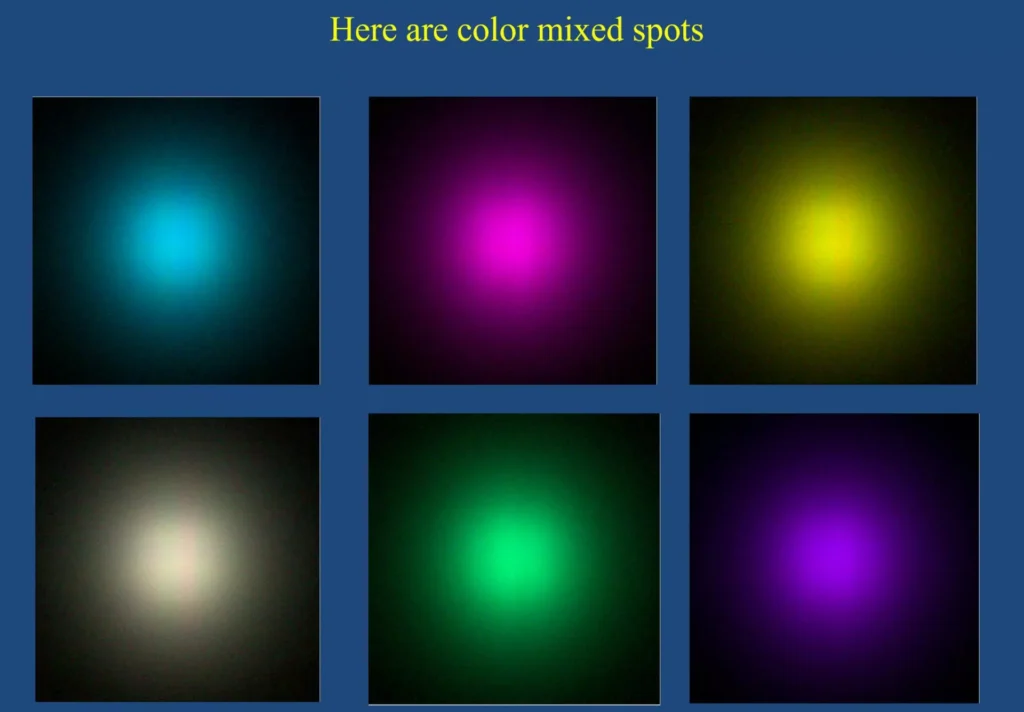

We still have high angles of light at the mixing rod. Some light is reflected back due to total internal reflection on the steep microlens surfaces: light is lost. To increase efficiency, we add some slope to the rod and the color mixed spots are improved. See images below.

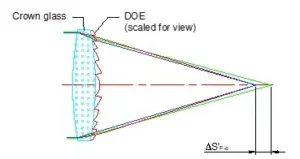

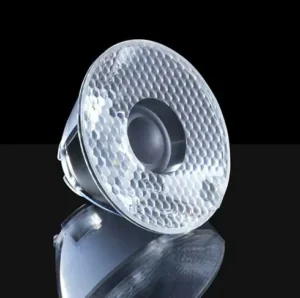

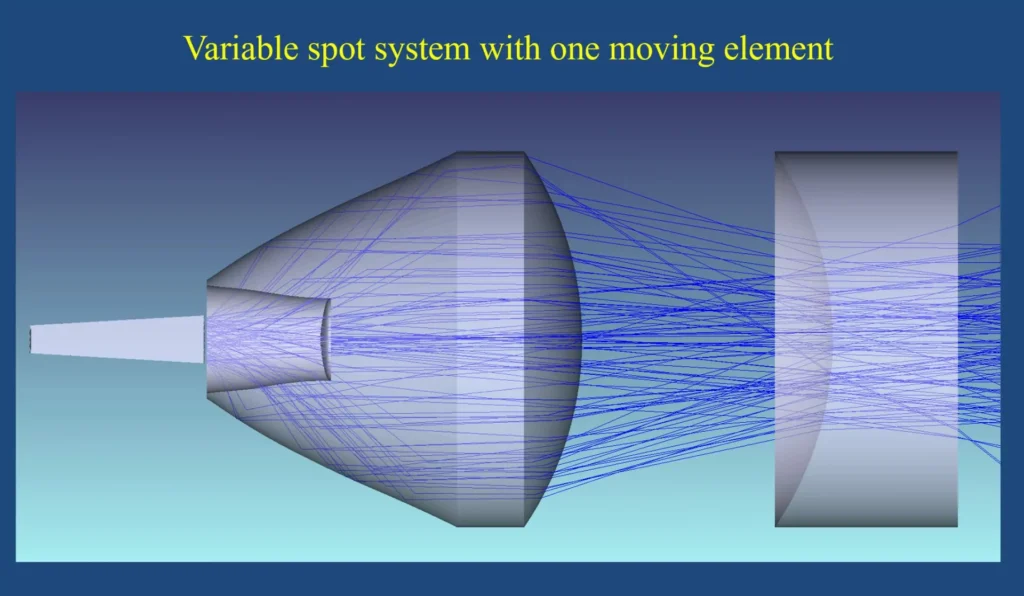

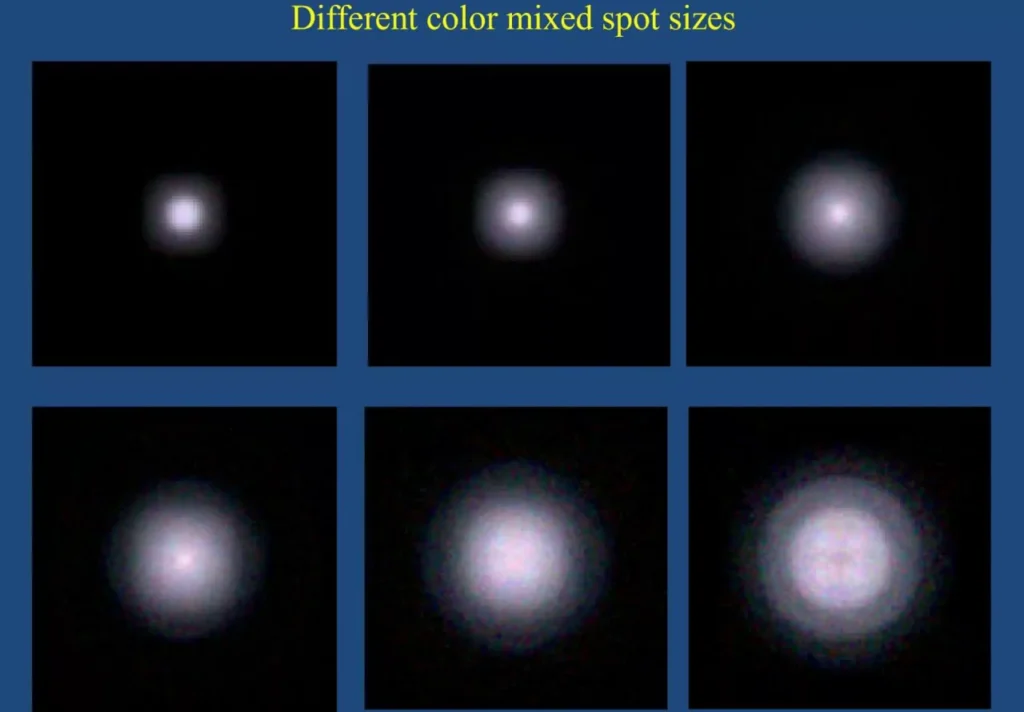

Achieving a Variable Spot with TIR Lenses and Asphere Concepts

Now that we have good luminous intensity color mix, we can use a TIR lens to collimate light. An asphere based concept can be used to provide variable spot system. The spot shown here is not perfect but can can be improved with additional optimization, or by adding more lens elements.

Need help? Click here to learn more about our custom illumination optic design services.