Introduction

You may not be aware but you probably have in your hands one of the toughest substances in the world right now. If you own a good quality watch chances are that it has a sapphire glass. Also, some versions of Appla watches and almost all mobile phones use sapphire lenses on their cameras. Sapphire, in its natural form, is a precious stone typically blue in color that is used in jewelry. However, sapphire can be created synthetically and it is this form that is endowed with valuable properties in many industries.

You may wonder what makes sapphire so special. I will go more in detail about its characteristics, but here I will present you with five reason why sapphire is so valuable

- is really really hard to scratch it. So it’s ideal for camera lenses and watches.

- Is almost completely transparent for a wide range of wavelengths (infrared to ultraviolet)

- It can stand a large range of pressure and temperatures without deformation.

- Very resistive to acids

- It can be synthetically manufactured

Why do we only see sapphire glass used in very limited applications? Why is it that our mobile phones don’t use sapphire instead of Gorilla Glass (™)? If you own a luxury watch, it probably has sapphire glass, but for the most part, sapphire use is not that widespread.

Well, sapphire is so hard, that is expensive to work with it.

If you are more interested to learn about sapphire, please read the rest of the article and ask us any questions in the comment sections

Optical and Mechanical Properties

One of sapphire’s most well known properties is its hardness. There are different ways to measure the hardness of a material. Two very common ones are the Mohs scale and the compressive/tensile stress. Mohs scale measures the resistance of a material against scratching. It is a qualitative scale with diamonds occupying its highest place, followed by silicon carbide, and, along with some other materials, sapphire in third place.

Mohs scale just measures how easy it is for one material to scratch another. There are harder synthetic materials like graphene but graphene is still not fully adopted in industry on a massive scale. An area where sapphire excels is its compressive strength: the pressure it can support before breaking. Sapphire has a compressive strength of around 2 GPa (or the equivalent of having 40 elephants stack on top of each other with the bottom one balanced on a single leg).

For comparison, steel has a compressive strength of 250 MPa (almost 8 times less than sapphire), and Gorilla Glass(™) (the industry standard for smart phone covers) has a compressive strength of 900 MPa (less than half of sapphire).

Also of interest is the fact that sapphire has excellent chemical properties being almost inert to all chemicals, making it suitable where corrosive materials are present. It has very low thermal conductivity, 25 W m^(-1) K^(-1), and extremely low thermal expansion coefficient, 5.8×10^6 / Celsius-Degree: it doesn’t deform or expand under high pressure or high heat conditions. Whatever your design is, you can be sure that it will have the same dimensions and tolerances at 100 meters under the sea or at 40K in orbit.

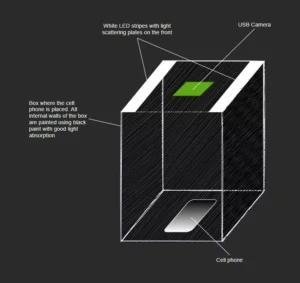

We have used theses properties of strength and scratch resistance windows for customer applications including industrial and medical lasers, underwater camera, and marine environment spectrometers.

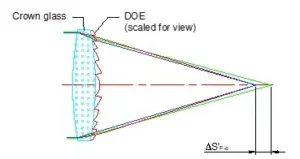

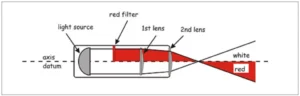

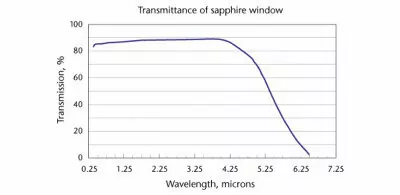

Sapphire glass has an excellent window of transmission in the 300nm to 5500 nm range (covering the UV, visible, and infrared region) with a peak in transmission of almost 90% at 300nm-500nm wavelengths. Sapphire is a birefringent material, so many of its optical properties will depend on the crystalline orientation. In its ordinary axis, its refractive index goes from 1.796 at 350nm to 1.761 at 750nm, and it has very small variations even with large changes in temperature.

Because of its good transmission and wide range of wavelengths, we have often used sapphire elements in infrared lens designs when more common glasses are not suitable.

If you are designing a satellite lens system where a wide range of extreme temperatures are present, a refractive index optical sensor for acids, a military display where protection from abrasive weather conditions is needed, or monitoring the conditions inside a high pressure chamber, sapphire glass will be your best choice.

Disadvantages

Because of its mechanical properties, sapphire is extremely difficult to work with. Creating large pieces of it is technically challenging and shaping it to specific geometries can be daunting. The same properties that make it so attractive also make it expensive.

Personally, we think that one of the reasons we don’t see more consumer electronics with sapphire is due to the nature of the market itself. Mobile phones, tablets, and laptops have a lifespan of less than 18 months before a new set of models are out in the market. Having a high end material like sapphire will make it extremely expensive for end users. High end watches, on the other hand, are meant to last decades, so using sapphire justify its costs. After several years, mobile phone companies like Apple and Samsung started using sapphire in their high-end products, but only as covers for their camera lens or on their smart watches.

Let us know in the comments if you have had the need to use sapphire in your designs, or if you own a device that has sapphire in it.

FAQs: Sapphire Glass

What is “sapphire glass” in optical engineering?

In optics, “sapphire glass” typically refers to synthetic sapphire (single-crystal Al₂O₃) used as a window, lens element, or protective cover. It is not glass in the amorphous sense. Its value comes from high hardness, broad optical transmission, and strong mechanical and chemical stability.

Why is sapphire used for watch crystals and camera lens covers?

Sapphire is highly scratch resistant, so it maintains surface quality and clarity over time. That durability matters in products exposed to everyday abrasion like watches and camera covers, where small scratches can degrade appearance and optical performance.

What wavelength range does sapphire transmit well?

Sapphire transmits across a broad band spanning UV through visible into infrared. In many optical contexts it is selected because it remains usable where common glasses begin to absorb, especially for systems that must transmit in UV or IR bands while also withstanding harsh environments.

When is sapphire a good choice for IR optics?

Sapphire can be a strong choice for IR windows or elements when mechanical durability, pressure resistance, or chemical inertness is required. It is often chosen when standard optical glasses are mechanically fragile or chemically incompatible with the environment, even if other IR materials may offer higher transmission in specific bands.

Why is sapphire popular for laser windows and high-power applications?

Sapphire’s hardness and strength make it well suited for protective windows in industrial or medical laser systems, especially when abrasion, cleaning, or mechanical stress is expected. With appropriate coatings and surface quality, it can protect internal optics while maintaining transmission and long-term durability.

What makes sapphire strong compared to materials like Gorilla Glass?

Sapphire has very high scratch resistance and high compressive strength. It also performs well under pressure and temperature extremes without significant deformation. These properties make it attractive for underwater, aerospace, and industrial environments where mechanical failure is a risk.

Why isn’t sapphire used for entire phone screens?

The main barrier is manufacturing and machining cost. Sapphire is difficult to grow in large flawless pieces and expensive to cut and polish. Consumer devices are cost- and cycle-time sensitive, so sapphire is often reserved for smaller high-value parts like camera covers rather than full displays.

What are the biggest disadvantages of sapphire in optical design?

The biggest disadvantages are cost and manufacturability. Sapphire is hard to machine into complex shapes, polishing can be slower and more expensive, and lead times can be longer. These factors can outweigh the performance benefits when the environment is not severe.

Does sapphire have optical properties designers need to watch for?

Yes. Sapphire is birefringent, meaning some optical behavior depends on crystal orientation. This can matter in polarization-sensitive imaging, interferometry, or systems where birefringence introduces unwanted phase effects. Orientation and specification details should match the application.

What applications commonly justify sapphire windows?

Common justifications include underwater cameras, marine spectrometers, high-pressure chambers, aerospace and satellite optics, corrosive chemical sensing, and ruggedized military or industrial displays. Sapphire is often used when a window must survive harsh conditions without losing optical clarity.

How should sapphire be specified for an optical window or lens element?

Typical specs include thickness, clear aperture, surface quality, flatness, wedge, crystal orientation, and the operating wavelength band. If coatings are required, specify coating type and durability expectations. Environmental requirements like pressure, temperature range, and chemical exposure should be stated up front.

When is sapphire overkill?

Sapphire can be overkill when the environment is benign and the main requirement is low cost or fast manufacturing. For many consumer-grade or indoor optical systems, common optical glasses can meet transmission and imaging requirements at much lower cost and with easier fabrication.