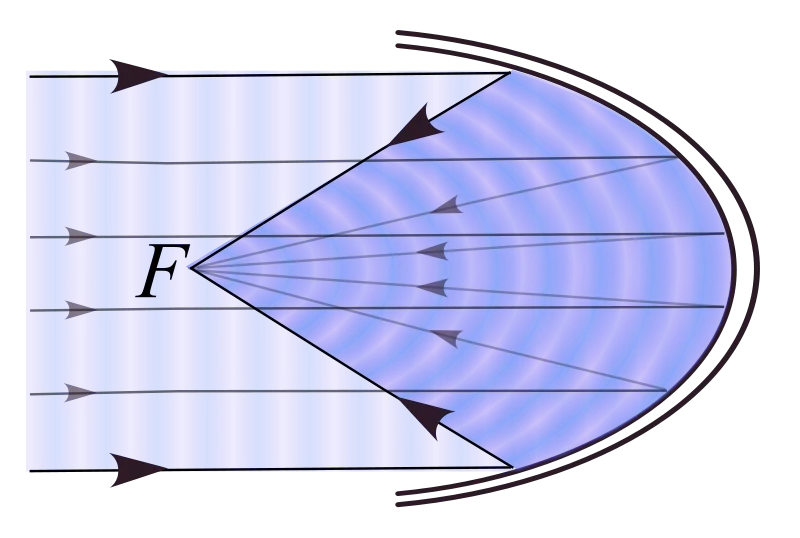

Parabolic mirrors are optical systems that are used to collect or distribute energy. They have a wide range of applications from solar collectors for water heating systems to microscopes and telescopes, and everyday flashlights. The most common way to understand parabolic mirrors is that a bundle of light beams parallel to the optical axis will reflect from the curved mirror surface and will focus on a single point. A parabolic mirror differs from a spherical one in that they greatly reduce spherical and coma aberrations.

Off-axis Parabolic Mirror

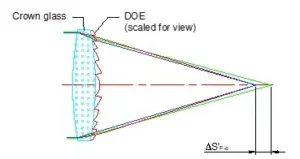

One not so obvious problem with systems that use parabolic mirrors is that the receiver/collector has to be placed at the parabolic mirror focal point creating a shadow at the mirror surface and limiting the amount of energy that can be collected. One solution to this problem is using off-axis parabolic mirrors.

Off-axis parabolic mirrors are basically sections of a parabolic mirror, usually a section that doesn’t include the vertex of the original parabola. The light beams are then focused away from the parabola in such a way that the receiver won’t create a shadow.

An important parameter when designing off-axis parabolic mirrors is the off-axis angle-the angle at which the light beams bounce off of the curved surface. The angle will depend on the section of the parabola that is used to create the off-axis mirror. The closer the section is to the parabola vertex, the smaller the angle will be.

When working with off-the-shelf optical components, this off-axis angle is limited to specific values (e.g. 15, 30, and 45-degrees). However, one of the advantages of having custom-made optics is that we can design this angle to your specific needs and use mirror coatings appropriate for the application and wavelengths.

To learn more about different mirrors used in optical systems, please see our previous post on ‘hot’ and ‘cold’ mirrors for UV and IR systems.

FAQs: Parabolic Mirrors

What is a parabolic mirror and how does it work?

A parabolic mirror is a reflective optical surface shaped as a paraboloid. Rays that enter parallel to the optical axis reflect and converge at a single focal point. This property allows parabolic mirrors to focus or collimate light efficiently without introducing spherical aberration.

Why are parabolic mirrors preferred over spherical mirrors?

Parabolic mirrors focus parallel rays to a single point, while spherical mirrors introduce spherical aberration that spreads the focus. Because of this, parabolic mirrors provide sharper focus and higher optical efficiency in applications such as telescopes, solar concentrators, and collimating systems.

When should a parabolic mirror be used instead of a lens?

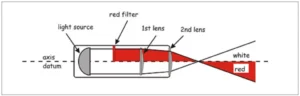

Parabolic mirrors are preferred when working across wide wavelength ranges or high power levels. Because reflection is wavelength-independent and avoids chromatic aberration, mirrors are ideal for broadband systems, high-energy applications, and environments where refractive materials are impractical.

What problem do off-axis parabolic mirrors solve?

On-axis parabolic mirrors require a receiver or detector at the focal point, which can block incoming light and create shadowing. Off-axis parabolic mirrors redirect the focus away from the incoming beam, eliminating obstruction and improving energy collection and system efficiency.

What defines the off-axis angle in an off-axis parabolic mirror?

The off-axis angle is determined by the section of the parent parabola used to create the mirror. Sections closer to the parabola’s vertex produce smaller angles, while sections farther away result in larger angles. This angle affects beam geometry and system layout.

How does the off-axis angle affect optical performance?

Larger off-axis angles increase asymmetry in the reflected beam and can introduce alignment sensitivity. Smaller angles are easier to integrate but may not fully eliminate obstruction. Selecting the correct angle balances performance, packaging constraints, and system efficiency.

What limitations exist when using off-the-shelf off-axis parabolic mirrors?

Commercial off-the-shelf mirrors are typically limited to standard off-axis angles, focal lengths, and coatings. These constraints can restrict system geometry or wavelength coverage, making custom designs preferable when tighter performance or packaging requirements exist.

Why do coatings matter in parabolic mirror design?

Mirror coatings determine reflectivity, durability, and wavelength performance. Selecting coatings optimized for UV, visible, or IR wavelengths improves efficiency and longevity. In high-power or harsh environments, coating choice directly affects system reliability.

What applications commonly use parabolic and off-axis parabolic mirrors?

Parabolic mirrors are widely used in telescopes, solar concentrators, illumination systems, collimators, and beam expanders. Off-axis designs are especially common in optical testing, spectroscopy, and systems requiring unobstructed optical paths.

What design factors are most critical when specifying a parabolic mirror?

Key factors include focal length, aperture size, surface accuracy, off-axis angle (if applicable), coating type, and alignment tolerances. These parameters collectively determine focusing performance, efficiency, and compatibility with the surrounding optical system.