A straightforward question, with no direct answer. The price of lenses depends on the design complexity, material, manufacturing process, and production series size.

A mass-produced lens, made from injection-molded plastic at volume 500,000 units, could cost $0.20 per element. At the same time, a glass lens with one element made in a batch of ten could cost $1000 per element.

Here are some pricing guidelines to consider:

1. Design costs: $1,500 – $75,000

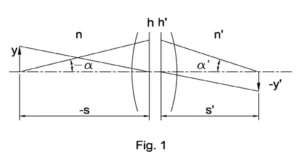

Design work consists of several phases before one can fabricate custom lenses. The process starts with concept development, then designing the lens elements, which are then arranged according to the optical layout. The tolerances are calculated and included in lens manufacturing drawings, which is followed by the development of an optomechanical design. Finally, the production drawings for the lens barrel and mechanical elements are created.

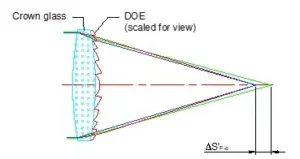

Designing each lens is a unique process. Besides traditional methods, custom lens design is typically made using state-of-the-art software tools, such as ray tracing programs like Zemax ( link to Zemax, or our page about Zemax design).

Since each custom lens must be designed before its production, that part of the expenses cannot be avoided. The design cost will be primarily driven by lens complexity – for example, is it one element lens or a 12 element UV objective lens? Furthermore, the cost is affected by design requirements, including resolution, distortion, F#, a field of view, and wavelength range. A high precision objective lens will cost much more to design than a single element relay lens.

2. Tooling costs: $0 – $30,000 per lens element

For plastic lenses made using injection molding, a mold needs to be developed, which can have a steep cost. Tooling cost is then dispersed across the (very large) batch, lowering its influence. Cost drivers include:

- application – imaging lenses have tighter tolerances and therefore higher costs than illumination lenses;

- volume – an eight cavity mold costs more than a single cavity mold.

When dealing with smaller volume glass lenses, universal tools are used for lens production, meaning that no special tools are needed. Often no setup and tooling cost is charged, and at most, the fees might be a few hundred dollars per lens element.

3. Lens production costs: $0.20 per unit to $75,000 per unit

Now that we have both the lens design and the necessary tools, it is time to produce. The production cost drivers include:

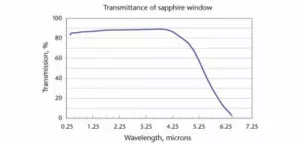

- materials – the glass prices can vary significantly, depending on the optical characteristics;

- production tolerances – narrower the tolerance, higher the price;

- mechanical parts – price increases with the part geometry complexity;

- assembly costs – more parts, higher the rate.

Despite the higher initial tooling costs, a plastic molded lens can be manufactured for a lower price when compared to a lens fabricated from glass – as long as the product quantity is large enough to justify the upfront tooling (NRE) costs to produce the custom optic mold.

Custom optics fabrication suppliers are located in the US, Europe, and Asia. Since suppliers often specialize in different materials, volumes, and quality. A custom design objective lens that requires high precision might best be produced by a custom lens manufacturer that specializes in that field. For this reason, it is imperative to carefully select the manufacturer matched to the task and provide clear requirements.

Need assistance designing a custom optic or imaging lens ? Learn more about our design services here.