A straightforward question, with no direct answer. The price of lenses depends on the design complexity, material, manufacturing process, and production series size.

A mass-produced lens, made from injection-molded plastic at volume 500,000 units, could cost $0.20 per element. At the same time, a glass lens with one element made in a batch of ten could cost $1000 per element.

Here are some pricing guidelines to consider:

1. Design costs: $1,500 – $75,000

Design work consists of several phases before one can fabricate custom lenses. The process starts with concept development, then designing the lens elements, which are then arranged according to the optical layout. The tolerances are calculated and included in lens manufacturing drawings, which is followed by the development of an optomechanical design. Finally, the production drawings for the lens barrel and mechanical elements are created.

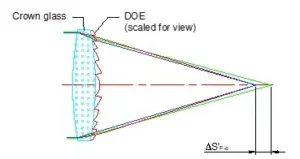

Designing each lens is a unique process. Besides traditional methods, custom lens design is typically made using state-of-the-art software tools, such as ray tracing programs like Zemax ( link to Zemax, or our page about Zemax design).

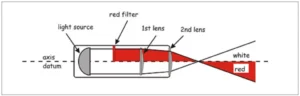

Since each custom lens must be designed before its production, that part of the expenses cannot be avoided. The design cost will be primarily driven by lens complexity – for example, is it one element lens or a 12 element UV objective lens? Furthermore, the cost is affected by design requirements, including resolution, distortion, F#, a field of view, and wavelength range. A high precision objective lens will cost much more to design than a single element relay lens.

2. Tooling costs: $0 – $30,000 per lens element

For plastic lenses made using injection molding, a mold needs to be developed, which can have a steep cost. Tooling cost is then dispersed across the (very large) batch, lowering its influence. Cost drivers include:

- application – imaging lenses have tighter tolerances and therefore higher costs than illumination lenses;

- volume – an eight cavity mold costs more than a single cavity mold.

When dealing with smaller volume glass lenses, universal tools are used for lens production, meaning that no special tools are needed. Often no setup and tooling cost is charged, and at most, the fees might be a few hundred dollars per lens element.

3. Lens production costs: $0.20 per unit to $75,000 per unit

Now that we have both the lens design and the necessary tools, it is time to produce. The production cost drivers include:

- materials – the glass prices can vary significantly, depending on the optical characteristics;

- production tolerances – narrower the tolerance, higher the price;

- mechanical parts – price increases with the part geometry complexity;

- assembly costs – more parts, higher the rate.

Despite the higher initial tooling costs, a plastic molded lens can be manufactured for a lower price when compared to a lens fabricated from glass – as long as the product quantity is large enough to justify the upfront tooling (NRE) costs to produce the custom optic mold.

Custom optics fabrication suppliers are located in the US, Europe, and Asia. Since suppliers often specialize in different materials, volumes, and quality. A custom design objective lens that requires high precision might best be produced by a custom lens manufacturer that specializes in that field. For this reason, it is imperative to carefully select the manufacturer matched to the task and provide clear requirements.

FAQs: Custom Lens Cost

Why is “How much does a custom lens cost?” hard to answer directly?

Lens pricing depends on design complexity, performance requirements, materials, manufacturing method, tolerances, and production volume. Two lenses can have the same focal length but very different cost if one needs high MTF, low distortion, tight alignment, or broadband transmission.

What are the main cost buckets for a custom lens project?

Most projects break into three buckets: optical and optomechanical design cost, tooling or setup cost (especially for molded optics), and per-unit production plus assembly cost. The total cost depends on how these are weighted by volume and performance requirements.

What typically drives optical design cost the most?

Design cost is driven by complexity and difficulty of the requirements. Examples include number of elements, wavelength range, f-number, field of view, distortion limits, resolution targets, and environmental constraints. A high-performance multi-element objective generally costs more to design than a simple relay lens.

Why do plastic injection-molded lenses have “tooling cost”?

Injection molding requires a mold, which can be a significant upfront non-recurring expense. That tooling cost is then spread across the production run. This model makes molded optics attractive at higher volumes, because the per-unit cost can become very low once the tooling is amortized.

When does molded plastic usually become cheaper than glass?

Molded plastic tends to win when volume is large enough to justify the mold cost and when performance requirements are compatible with polymer optics. For low volumes or demanding imaging performance, glass fabrication can be more economical and lower risk.

Why can two “glass lenses” have drastically different per-unit prices?

Glass lens cost varies with glass type, coating needs, surface figure, surface quality, centration, and tolerance tightness. A lens produced in a small batch with tight tolerances and complex geometry can cost orders of magnitude more than a simple element made with relaxed tolerances.

How do tolerances impact the final manufacturing quote?

Tighter tolerances increase cost because they raise manufacturing time, scrap risk, inspection burden, and alignment complexity. In many designs, a small relaxation in one or two tolerances can reduce cost substantially without meaningfully changing system performance if tolerance analysis supports it.

What parts of the system often get overlooked in “lens cost” discussions?

Mechanics and assembly can dominate cost, especially for multi-element designs. Barrel complexity, spacers, retainers, alignment features, and assembly labor all add up. Even if glass elements are modestly priced, precision assembly and verification can be the main driver.

How does production volume change pricing strategy?

Low volumes tend to emphasize minimizing NRE and simplifying fabrication and assembly. High volumes shift focus to tooling, yield, cycle time, and per-unit cost optimization. A design that is “best” for ten units is often not the best design for 100,000 units.

Does supplier location matter for custom lens cost?

It can. Suppliers differ by specialization, material strengths, quality systems, lead times, and metrology capability. The best supplier choice often depends on whether the lens is an imaging objective, an illumination optic, a window, a coated element, or a high-precision assembly.

What information is needed to get a meaningful quote?

A meaningful quote typically requires wavelength range, field of view, f-number, resolution or MTF goals, distortion targets, working distance, sensor details, environmental constraints, expected volume, and packaging constraints. Without these, quotes tend to be broad ranges rather than actionable numbers.

What is the fastest way to reduce cost without breaking performance?

The fastest lever is usually requirements clarification and tolerance optimization. If the true must-haves are separated from nice-to-haves, designers can simplify the solution. Reducing element count, relaxing non-critical tolerances, simplifying coatings, or increasing manufacturability often yields large savings.

What’s a practical expectation for unit price ranges?

Per-unit cost can range from cents for high-volume molded elements to thousands for low-volume, high-precision glass optics. The useful takeaway is that unit price is inseparable from volume and specification, so cost discussions are most productive when those are stated explicitly.

Need assistance designing a custom optic or imaging lens ? Learn more about our design services here.