Introduction to f-theta Lenses

In the landscape of optical systems, the introduction of f-theta lenses is an important chapter, offering a solution to the challenges posed by traditional lenses in laser scanning applications. As laser technology becomes more prevalent in applications from engraving to intricate material processing, the need for precision and consistency in focused laser beams is essential.

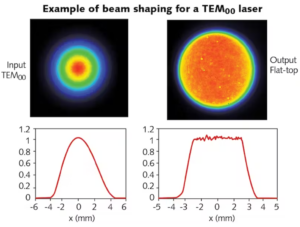

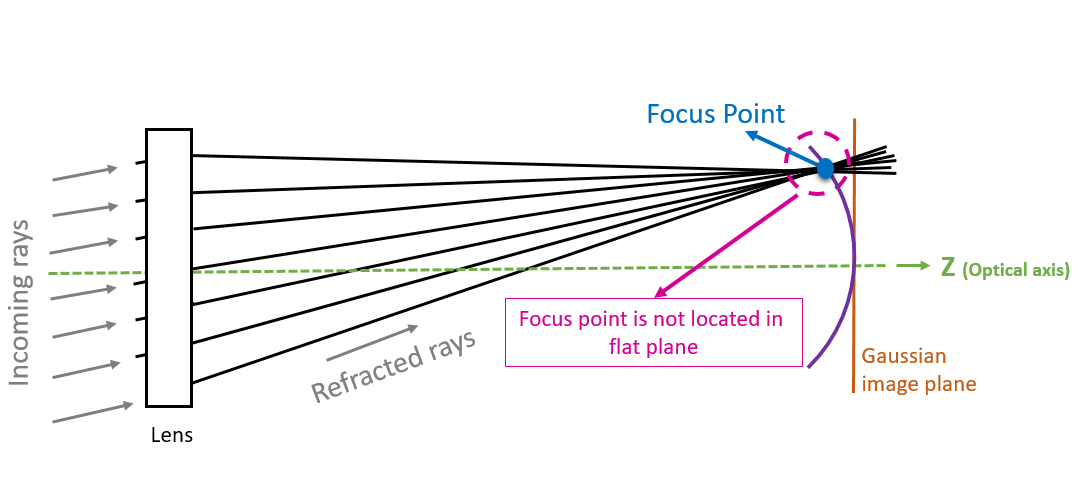

Traditionally, scanning systems employing galvanometers or scan mirrors facilitated linear movements of laser beams, enabling diverse applications such as engraving, drilling, and cutting. However, the use of conventional lenses in these setups introduced a critical drawback. As the laser beam deviated from the optical axis, the profile of the focused beam underwent unwarranted changes. This phenomenon, rooted in the lenses focusing light on a curved surface, not only contributed to aberrations like field curvature but also led to alterations in the optical power on the material’s surface. These fluctuations, in turn, manifested as errors in the manufacturing process.

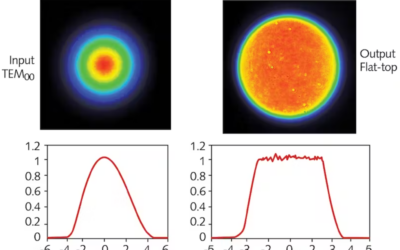

The evolution of f-theta lenses emerged as a transformative solution to this challenge, rewriting the narrative of precision in laser systems. The unique design of f-theta lenses ensures that the focused laser beam maintains a constant spot size across the entire scanning field, irrespective of its deviation from the optical axis. This characteristic, stemming from the lens’s ability to create a flat field, not only mitigates optical errors but also enhances the accuracy and uniformity of laser processing on various materials.

Figure 1. Image plane of a traditional image system. The focal point of a regular lens is a curved plane.

A way to solve this problem is by using what is called “flat-field” scanning lenses that focus light in a flat plane at the focal point. However, traditional flat-field lenses create an image that is proportional to the lens focal point and to the scanning angle tangent. That means, as the scanning angle changes linearly, the image will not move linearly. This can also cause manufacturing errors.

1. LIDAR (Light Detection and Ranging):

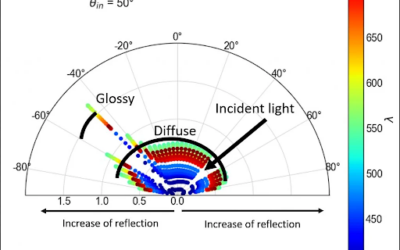

In the realm of LIDAR, f-theta lenses emerge as vital components for ensuring precise laser beam steering. The flat field produced by these lenses enables accurate distance measurements and 3D mapping. In automotive applications, for instance, f-theta lenses contribute to enhanced object recognition and collision avoidance systems. The evolving trend in LIDAR technology involves the integration of f-theta lenses in compact and efficient LIDAR systems for autonomous vehicles, offering a harmonious synergy between precision and miniaturization.

2. Scanning Laser Microscopy:

F-theta lenses find extensive use in scanning laser microscopy, facilitating high-resolution imaging with minimal distortions. In biological research, these lenses play a crucial role in capturing detailed cellular structures. Ongoing trends involve the incorporation of f-theta lenses in advanced microscopy systems, enabling faster and more accurate imaging. Additionally, the integration of adaptive optics with f-theta lenses is an emerging technology, enhancing the correction of aberrations and pushing the boundaries of imaging capabilities in microscopic studies.

3. Optical Coherent Tomography (OCT):

In the field of OCT, f-theta lenses contribute to the precision required for non-invasive imaging of biological tissues with micron-scale resolution. Applications range from ophthalmology, where f-theta lenses aid in retinal imaging, to dermatology and cardiology. A notable trend involves the development of ultra-compact OCT systems utilizing f-theta lenses, catering to point-of-care diagnostics and expanding the accessibility of high-resolution imaging technologies.

Emerging Trends and New Technologies:

Across these applications, a prominent trend involves the integration of f-theta lenses with advanced materials and coatings to enhance performance. In LIDAR, the incorporation of diffractive optical elements alongside f-theta lenses is gaining traction, allowing for more complex beam shaping and improved LIDAR system efficiency. In scanning laser microscopy and OCT, there is a surge in the adoption of computational imaging techniques combined with f-theta lenses, enabling faster data acquisition and enhanced image processing capabilities. Moreover, the development of tunable f-theta lenses, allowing real-time adjustments of focal lengths, is an exciting avenue for achieving greater flexibility in various optical applications.

As f-theta lenses continue to evolve, these advancements underscore their critical role in shaping the trajectory of precision optics across diverse industries, offering unparalleled accuracy and reliability in cutting-edge technologies.

They are called f-theta lenses because the image height created by these lenses is linearly proportional to the focal length and the scanning angle theta .

Figure 2. Difference in the focal plane for a convention lens, flat field scanning lens, and f-theta lens (image source Thor Labs)

Selecting an F-Theta Lens

Selecting the ideal f-theta lens is a critical step in optimizing laser systems for various applications. Several factors must be considered to ensure compatibility, durability, and optimal performance.

1. Material Considerations:

The choice of lens material is pivotal in achieving the desired optical properties. Fused silica and ZnSe are common materials for f-theta lenses. Fused silica offers excellent transmission in the UV range and is suitable for applications like semiconductor processing. ZnSe, on the other hand, is advantageous for mid-infrared applications. Understanding the wavelength range of your laser system is crucial, ensuring the selected material provides optimal performance.

2. Coatings and Durability:

Coatings play a crucial role in enhancing transmission efficiency and reducing reflections. Anti-reflective coatings tailored to the laser wavelength improve overall system performance. Additionally, protective coatings can enhance durability, safeguarding the lens against environmental factors and contaminants. Assess the coatings offered by manufacturers to align them with the specific demands of your application.

3. Compatibility with Laser Systems:

Consider the laser system specifications, such as beam diameter and power levels, to ensure compatibility with the f-theta lens. The lens should be capable of handling the power density and beam characteristics of your laser source. Check if the lens is designed for continuous-wave (CW) or pulsed laser applications, as different requirements may dictate distinct lens designs.

4. Focal Length and Spot Size:

The focal length of the f-theta lens determines the size of the focused spot on the target. Assess the working distance and spot size requirements for your application. It’s essential to strike a balance between the desired spot size and working distance to achieve optimal results.

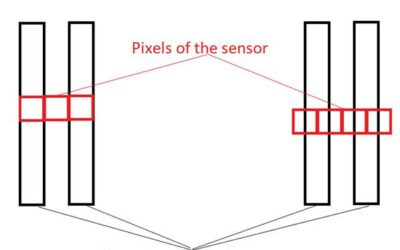

5. Field Size:

Consider the required field size for your application. Different f-theta lenses may offer varying field sizes, and selecting the appropriate lens ensures that your laser beam covers the entire scanning area without distortion.

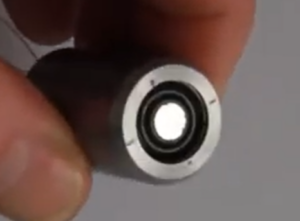

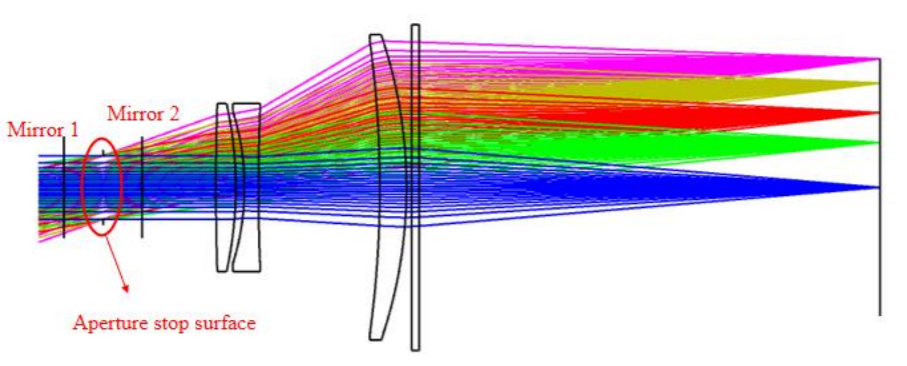

Figure 3. Example of a telecentric f-theta lens

(Please see this article for a detailed explanation of wide angle lens types including about f-theta lenses)

Conclusion

In this comprehensive exploration of f-theta lenses, we’ve unraveled the mechanics and applications of these crucial optical components. F-theta lenses, designed for precision in laser systems, offer a flat field that ensures consistent spot sizes and unparalleled accuracy in applications ranging from LIDAR to scanning laser microscopy and optical coherence tomography.

Selecting the right f-theta lens involves a nuanced consideration of factors such as lens materials, coatings, compatibility with laser systems, focal length, and field size. The choice of material, including fused silica or ZnSe, impacts transmission efficiency, while coatings play a pivotal role in enhancing durability and performance.

As you navigate the intricate landscape of precision optics, consider the unique specifications outlined in the comparison chart to guide your selection process. Balancing the focal length, spot size, and field size according to your application’s demands is key to optimizing the performance of your laser system.

For tailored solutions and custom lens designs, we invite you to consult with Optics for Hire. Their expertise in optics and commitment to delivering cutting-edge solutions make them the ideal partner for addressing your specific optical needs. Explore their services for a seamless integration of precision and innovation in your optical endeavors. Discover the difference that precision optics can make and elevate your projects with Optics for Hire’s dedicated team of experts.

FAQ About 4f Optical Systems

What exactly is a 4f optical system?

A 4f optical system is a configuration in optics that uses two lenses to perform Fourier transformation on an image. This setup allows for various image processing techniques, including filtering and pattern recognition.

How does a 4f system apply Fourier optics in practical applications?

In practical terms, a 4f system uses the principles of Fourier optics to transform an image into its frequency components, enabling targeted manipulation like noise reduction or feature enhancement. This is useful in fields like signal processing and medical imaging.

Can 4f optical systems be customized for specific needs?

Yes, 4f optical systems can be tailored for specific applications by adjusting components like the focal length of lenses and the types of masks used in the Fourier plane, allowing for a wide range of customized solutions.

- Laser Beam Caustic/Discover the intricacies of laser beam caustics. Unveil how they determine laser beam quality and their importance in various laser applications.

- Hot and cold mirrorsExplore the innovative use of hot and cold mirrors in managing UV and IR wavelengths. Understand their critical role in enhancing optical system performance.